Description

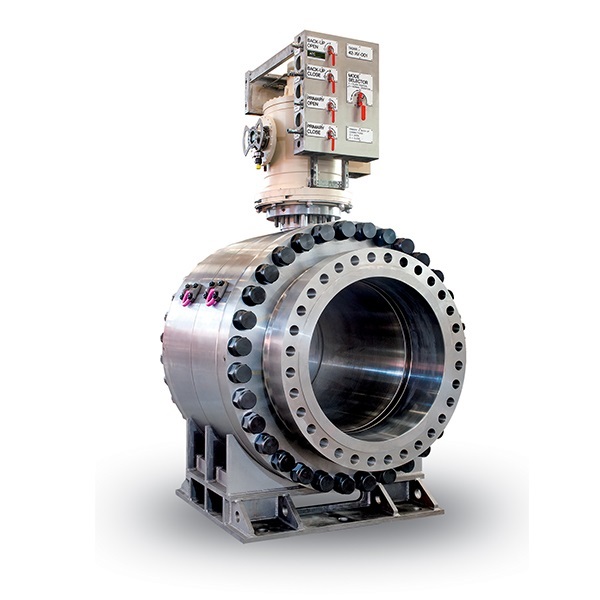

A Welding Neck (WN) Flange is a type of flange used in piping systems to connect pipes and equipment together. It is designed to be welded to the pipe or fitting and then bolted to another flange or piece of equipment. The WN flange has a long tapered neck that is welded to the pipe or fitting, and a flat face that extends out from the neck. The flat face of the flange provides a surface for the gasket to seal against, and the bolts are tightened to compress the gasket and create a leak-tight seal. The neck of the WN flange also provides reinforcement to the connection, which makes it suitable for use in high-pressure and high-temperature applications. The tapered design of the neck reduces stress concentrations and distributes the load evenly across the flange, which helps to prevent leaks and failures.

Specification

Standard: ASNI/ASTMB16.5/16.36/16.47A/16.47B B2220-2001, DIN2527/2636/2637/2638/2566/2576/2633/2635/2642/2653/2655.

Pressure Rate: 150LBS to 2500LBS / PN10 to PN400

Dimension: 1/2" to 48"

Material: Carbon steel, Alloy Steel, Stainless steel.

Sealing type: RF, FF, MFM, TG, RTJ

WENZHOU WEITUO VALVE CO., LTD.

WENZHOU WEITUO VALVE CO., LTD.