-

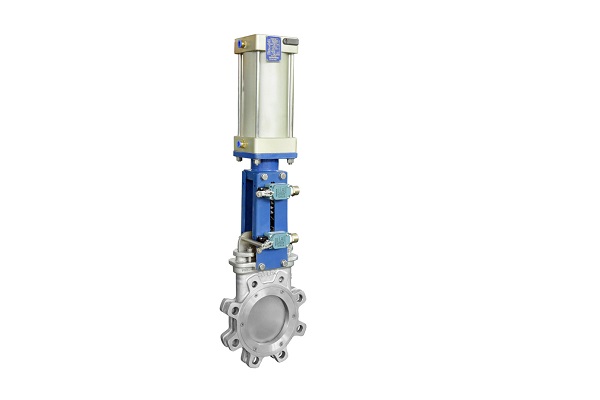

Precautions for installation and use of knife gate valve and application of knife gate valve

Knife gate valves are mostly used in some difficult-to-control fluid pipelines, such as sewage, chemical, coal, papermaking and other fields.… -

Feasibility of replacing gate valve and globe valve with double eccentric hemispherical ball valve

The double eccentric hemispherical ball valve has a unique design, novel structure, and the scope of orders is constantly expanding.… -

The difference between butt welding valve and socket welding valve

Socket welding is to insert one end of the pipe into the object to be welded with it, which is good for positioning, good welding and high strength.… -

Duplex stainless steel valve performance characteristics

The duplex stainless steel valve has the advantages of both the ferritic stainless steel valve and the austenitic stainless steel valve, and it combines the excellent toughness and the austenitic stainless steel valve.… -

Appearance and structural characteristics of eccentric hemisphere valve

The eccentric hemispherical valve is a top-loading structure. The valve installed on the pipeline can be directly inspected and maintained online, which can effectively reduce the shutdown of the device and reduce the cost.… -

Lift check valve installation method and installation and maintenance

Lift check valve refers to a valve that automatically opens and closes the valve flap by relying on the flow of the medium itself to prevent the backflow of the medium, also known as check valve, one-way valve, reverse flow valve, and back pressure valve.… -

Three major characteristics of soft sealing gate valve

The soft sealing valve gate itself is a kind of valve with strong sealing performance. Its characteristics are widely reflected in other aspects.… -

Explore the reasons for the use of long-neck bonnets for cryogenic valves

The cryogenic valve adopts the long-necked bonnet superior. The output liquid low-temperature medium, such as ethylene, liquid oxygen, liquid hydrogen, liquefied natural gas, liquefied petroleum products, etc.…

WENZHOU WEITUO VALVE CO., LTD.

WENZHOU WEITUO VALVE CO., LTD.